GHOST-1

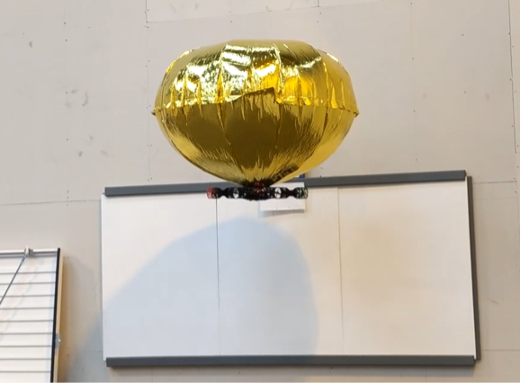

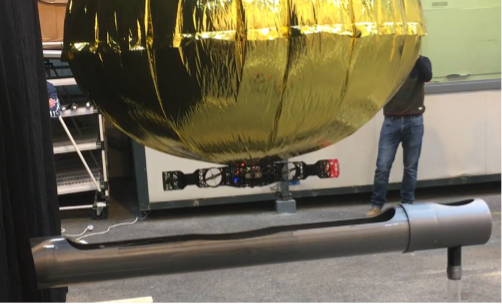

Lighter Than Air Surveillance Drone (LTASD)

The LTASD project was started back in 2017 in collaboration with Sheffield University, funded through Innovate UK. The challenge was to create technology capable of remote access into a nuclear facility to characterise defects, debris, objects and layout. The task was further restricted by the need to access the nuclear facilities (like those found at Sellafield) through 6” ports in the wall.

It was decided that the to maximise flight time and prevent kicking up a lot of dust and debris that the best solution would be to develop a lighter than air drone. This drone could be inserted into the facility, inflated and then deflated once the mission was accomplished. FIRMA started conducting trials using scaled prototypes to work out the best means of wrapping the collapsed envelope after deflation. It was this early prototype work which started FIRMA’s ongoing research into 3D printing.