FIRMARM

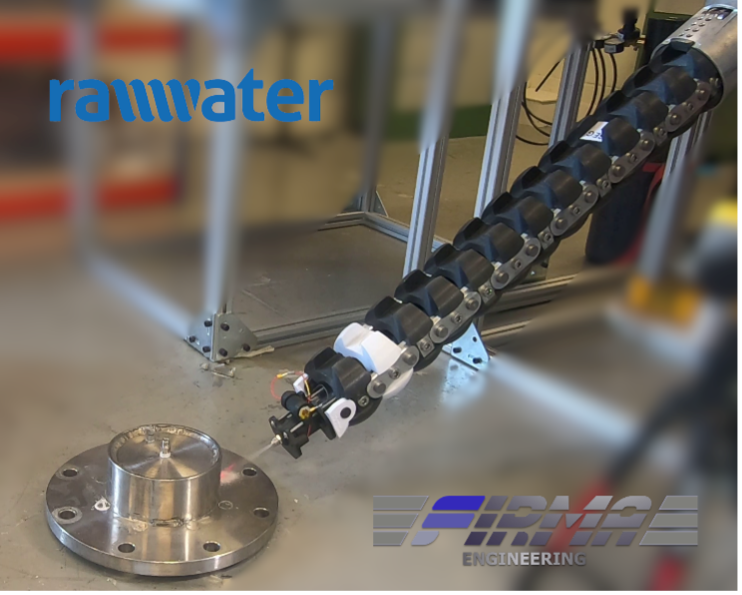

“Flexible Interchangeable Reconfigurable Mechanical Arm”

The FIRMArm’s genesis can be dated back to October of 2019 when the concept was submitted as a response to the Game Changers “Remote working at height in hazardous areas” challenge.

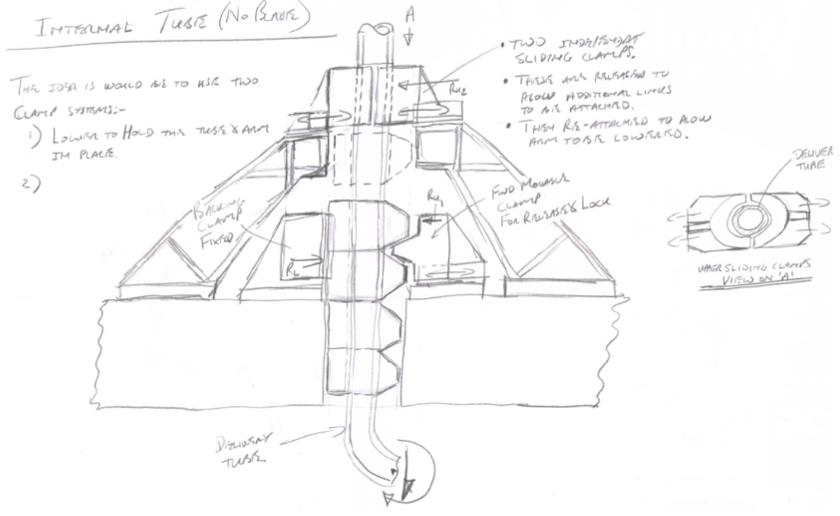

The challenge was to develop a cost-effective modular toolkit for cell inspections/POCO (Post Operational Clean Out) operations. The key functional requirements of this challenge were:

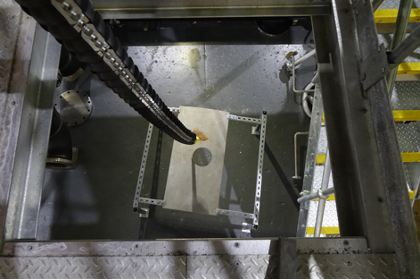

- Modular design to allow deployment, and potentially self-assembly, in multiple scenarios whilst preferably operating as a single platform.

- Capable of working at height (<25m for cells, <5m for gloveboxes) in a congested area.

- Ability for the commercial device to operate for extended periods in a radiation environment.

- Carry a total payload (end effector and debris) of >5kg, at distance.

- Ability to accept a variety of end effectors:

- Compatible with end effectors which can perform characterisations tasks e.g. radiometric, chemical, visualisation etc.

- Compatible with end effectors which can hold, cut, transfer and retrieve material.

- Ability to be deployed and retrieved through an inspection port approx. 150mm diameter.

- Ability to operate without line of sight and communicate outside the cell or glovebox.

- Ability to be scaled [desirable].