Bringing a range of technical and organisational skills honed over many years delivering high profile aerospace projects FIRMA Engineering Ltd provides a design solution from concept through to certification analysis.

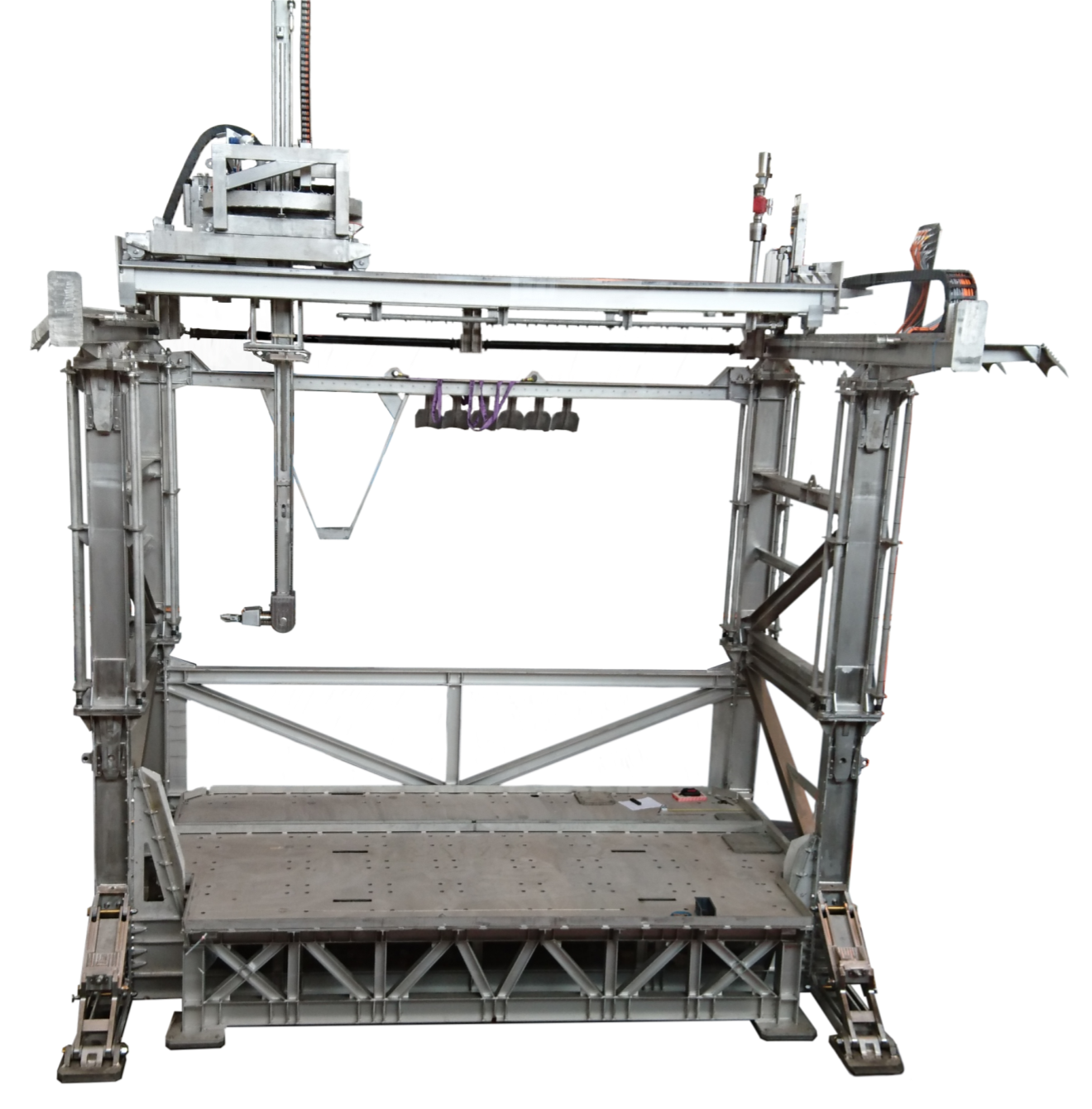

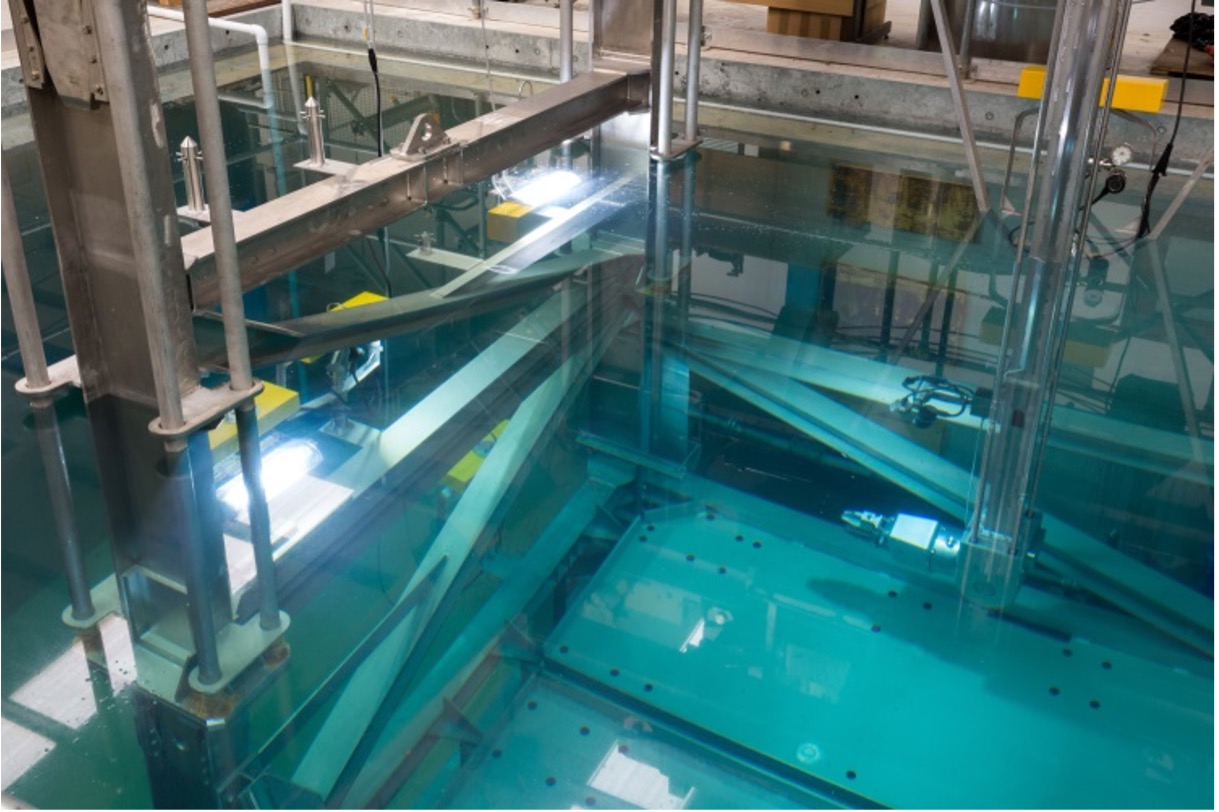

SSCC Assembly Complete – Showing Tool and Skip Tables in position

Once the initial challenges faced in gaining acceptance from the end user (Sellafield Ltd) were overcome, FIRMA were recognised as a suitable partner to work along-side (VNS-UK) to develop a radical engineering solution to support their bespoke remote handling equipment, in the form of a modular Gantry Frame and Table.

In early 2015 FIRMA Engineering were approached by the Technical Director of Veolia Nuclear Solutions (VNS), Simon Mills (then Oxford Technologies), to help with the development of the Sort Segregate Condition & Consolidation (SSCC) for the First Generation Magnox Storage Pond (FGMSP) located within the Sellafield estate. As a micro SME and a recent entrant to the Nuclear Supply Chain, FIRMA were keen to make an impression in the industry.

If it has difficult site access, requires delivery through a letter box and assembly below water in a hostile environment then FIRMA Engineering are ideally placed to rise to such a challenge.

VNS-UK, specialist in working in difficult, hostile environments, appropriated the support from FIRMA, who’s proven success in working with unique technical challenges, allowed them to contribute on a number of levels. The task was not confined to the usual engineering design and analysis activities. There existed additional challenges to align technical specifications in the form of methods and loads documents, lending structure and accountability to the project, and satisfying the strict conformance criteria laid down by the customer. From the early stages, FIRMA identified this as an essential aspect of guiding the design to a successful conclusion.

Despite the constraints presented due to time restrictions and some of the technical anomalies, FIRMA as a Micro SME, were able to offer a flexible approach to the design process, something that larger organisations which provide similar services would find difficult. This involved constantly managing and adapting to changing information flowing down from the customer (VNS-UK) and end user (Sellafield).

Key milestones in the project included:

– Conduct a preliminary structural assessment of the initially proposed concept.

– Identifying which aspects were essential to support the actual functional requirements.

– Gaining the confidence and agreement of stakeholders, to offer a completely new concept.

– Delivering a new solution which embodied the essential aspects of a design, as per the key requirements identified.

Challenges faced which were unique to this project include:

– Site, building and pond access restrictions driving the requirement for a highly deployable modular design including separate skip tables and gantry frame.

– The requirement for construction below the water line, in a hostile environment leading to innovative, remote assembly methods to be incorporated into the design.

– Balancing the requirements for an open (C-Section) gantry to allow skip access, while designing for limited deflections in the frame, to avoid issues with operational functionality.

By understanding the technical requirements and using a logical design approach, FIRMA were able to evolve a structural design that satisfied the pond entry envelope restrictions, together with the assembly, environmental and operational constraints.

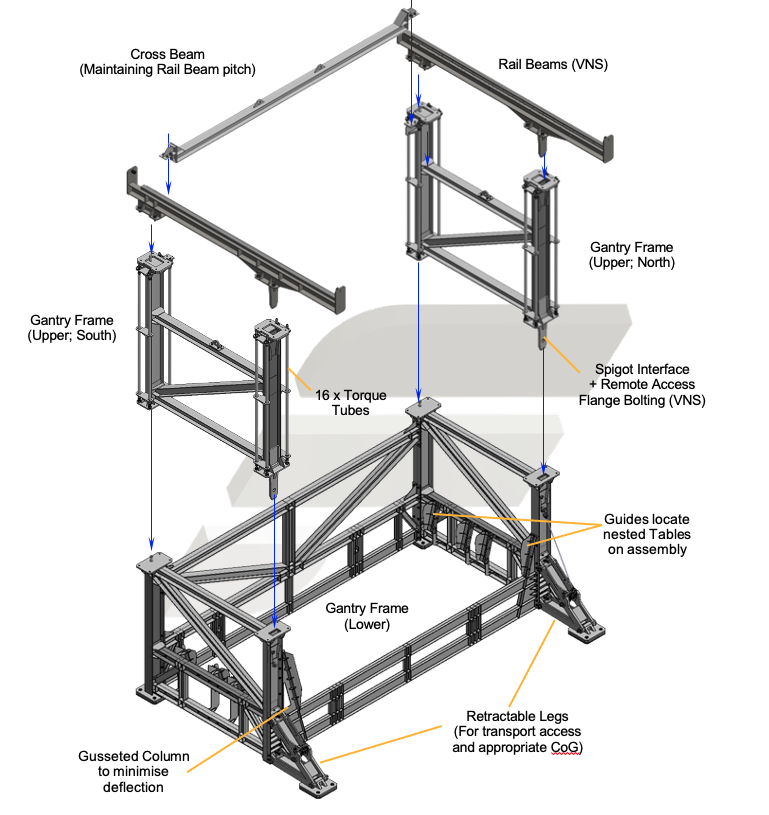

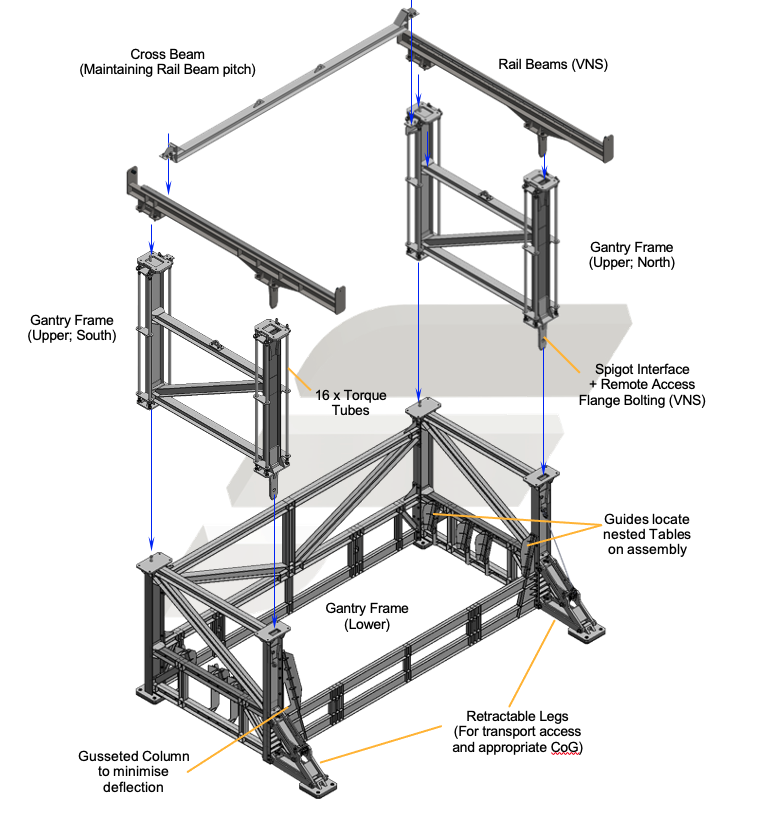

The following diagram illustrates all structural items below the Gantry Rails which FIRMA were responsible for from a structural design and analysis point of view.

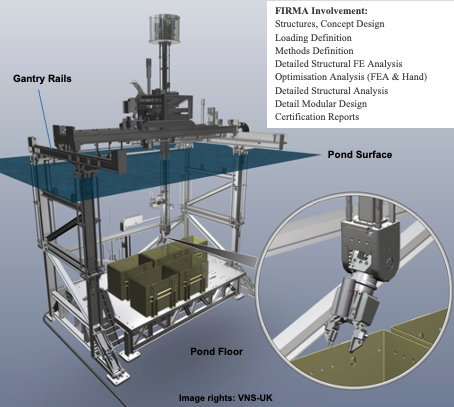

SSCC positioned in FGMS Pond (showing waste skips)

The FIRMA modular design allows for the structure to be brought into the FGMS Pond in stages, which is then assembled from the pond floor up.

Retractable legs are used to ensure unrestricted access to the pond during transit, and to ensure a safe CoG position during operation. Spigot locators aid assembly positioning. Torque Tubes for below waterline bolting during assembly. Cross Beam to ensure that Rail Beam side to side pitch is maintained during operation.

Tool Table (west) & Skip Table (east) are designed to be lowered into the lower half of the Gantry Frame and are guided into position via the integral guides.

Three years after completion of the design, FIRMA are delighted to hear that the testing phase has been completed and the complete machine has now been installed at Sellafield and is ready for operation.

SSCC Installed in VNS-UK Test Pond

Using the opportunity provided through Simon Mills to support VNS-UK, FIRMA Engineering Ltd has proven that it has the experience and innovative talent to deliver on even the most challenging of projects. Having this opportunity has greatly improved our understanding of the nuclear decommissioning industry and has helped to establish FIRMA as a trusted part of the nuclear supply chain.